| Application | Industrial packaging, living goods packaging |

| Machine Size | L7,500*W3,400*H6,100mm |

| Machine Weight | 23 tons |

| Platen Size | L1,260*W960mm |

| Maximum Product Height | 130 mm |

| Maximum Hot Press Clamping Force | 40 tons |

| Platen Parallelism Flatness Specification | ≦0.35 mm |

| PLC and Software | Siemens or equivalent, programs can be modified by remote modules |

| Upgraded Safety Features | Safety relay and emergency stop button |

| Suction/Hot Press Dynamic Mode | Servo motor hydraulic drive, 21.5kW+18.2kW |

| Hot Press Drive Mode | Servo motor drive, 3.5kW |

| Total Rated Power | 145kW |

| UPH | ≈ 3,600 pcs (Earbud tray:80 sec cycle time, 80 cavities) |

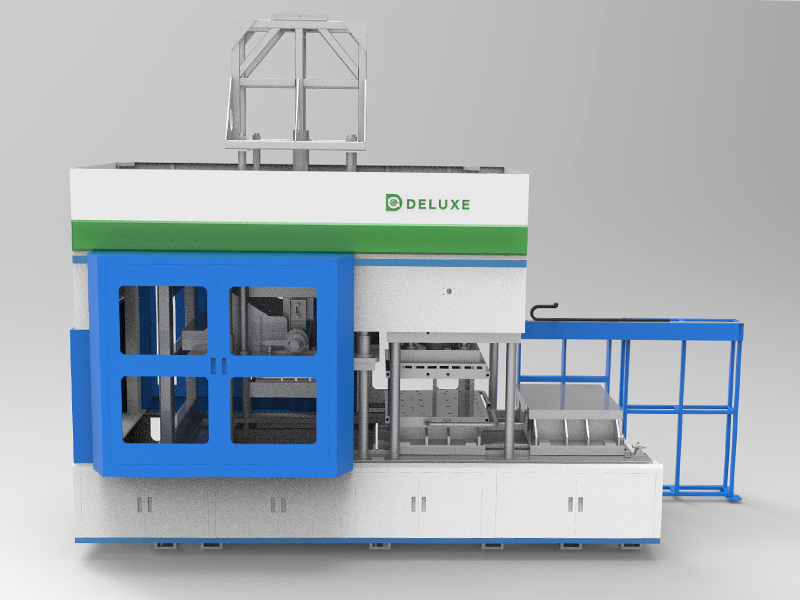

FA02-A

Small draft angle production for high-end eco-friendly molded fiber packaging.

0 degree draft angle. Corner radius ≧0.5mm. High positioning accuracy. Equipped with cold press. High-quality, smooth and flat on both internal and external surface of the product.

Fast speed. High precision. Easy control.

Fully servo drive with high positioning accuracy. Production movement fast and stable.

Energy-efficient and high capacity. Small occupied area.

Suction and hot press transfer both driven by servo motor which benefits on energy saving. Daily capacity : 600~900 kg/day (Varies depending on the product type). Occupy 25.5 square meters only.

Simple maintenance

Equipped with auto oil adding system. Pipeline arrangement compact and organized. Maintenance process clear and simple. Each area has equipped with corresponding channel and gate to facilitate the repair and maintenance work.

Safe and easy to operate

The program is equipped with interlocking and alarm system on the safety doors. Easy to operate and maintain with fully automatic PLC control screen.