Innovative Process and Production Technology

- Small Degree Draft Angle

- High-precision Tooling

- Seeking Cost Reduction Methods for Sustainable Products

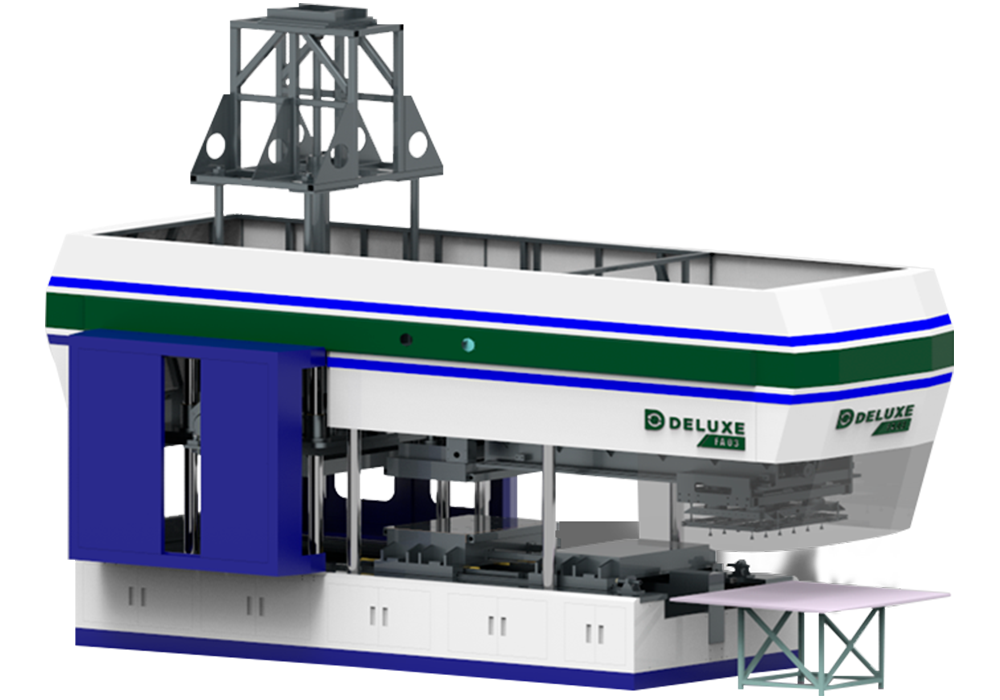

- Automated Intelligent Solutions

We incorporate the concept of environmental protection into entire product manufacturing process, from raw materials, molds, processes, designs, and production. While achieving packaging excellence, we proactively practice energy conservation and carbon reduction, aiding our clients in enhancing both product quality and brand image.

A Smoothness on Par with Plastic.

Advantages of Molded Fiber Technology.

By adopting the wet pressing molding technique instead of the conventional dry pressing process, our products exhibit a superior level of quality and surface smoothness compared to typical products in the market. We proudly stand as the pioneering and sole company with the ability to achieve a one-piece molding for molded fiber products exceeding 1.6mm in thickness, and a draft angle less than 1.5 degrees!

Cost Reduction, Quality Enhancement

Utilizing unique technology, we manufacture molded fiber products with paper usage reduced by 20% compared to traditional methods, while achieving higher quality in terms of compressive strength and extensibility. Our advanced tooling technology and quality have been recognized by several international high-end electronic product manufacturers, designating us as their supplier for molded fiber packaging materials, tooling and equipment.

Acquired Numerous Patented Technologies

Successfully passed testing and verification by international-level manufacturers of high-end electronic products (such as desktop computers, laptops, tablets, phones, etc.) using plant fiber materials instead of plastic packaging. Met all the technical and quality benchmarks required by their products and smoothly transitioned into mass production.